Main engine and traction unit adopts inverter to adjust speed and save energy. Surface friction single roller is used to make plastic film smooth and neat, and clean. This machine enjoys many advantages, such as improving effeciency, saving costs and investments, saving costs of labors and lands and etc. This machine is used for blowing plastic film such as LDPE, HDPE, and LLDPE.

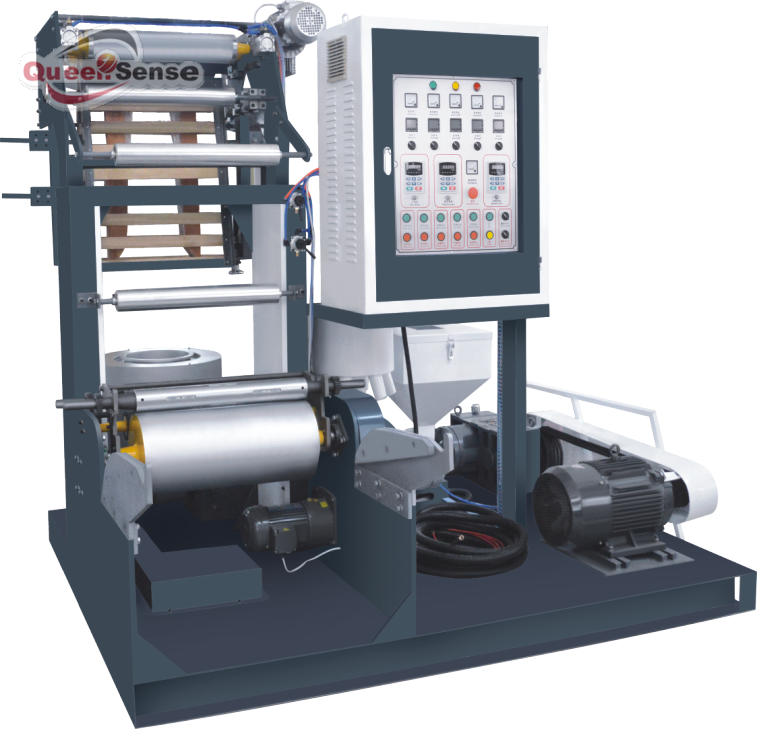

Mini Film Blowing Machine:

1. This film blowing machine is scientifically designed. The extruder, barrel and screws are made of high-quality 38CrMoAI alloy steel.

2. After nitridation and precision finishing, screws are of great hardness and corrosion resistance, ensuring a high quality in production and Plasticizing.

3. Main engine and traction unit adopts inverter to adjust speed and save energy. Surface friction single roller is used to make plastic film smooth and neat, and clean.

4. This machine is used for blowing plastic film such as LDPE, HDPE, and LLDPE. Finished material is widely used in the wrapping of food, cloth,and industry field.

5. Rotary die is optional. With this auxiliary equipment, the thickness of plastic film can be adjusted.